Industry 3.0 has proven to be a boon for industries such as aerospace, pharma, automobiles etc., however, apparel manufacturing industry hasn’t unlocked its true potential as of yet. When someone mentions about ‘automation’ in the apparel industry, the chances are high that most of the industry’s decision-makers still think it’s all about robots working on shopfloor which is not the case. By analysing hundreds of definitions of automation coined by different organisations and reports, one can sum up the following definition of automation in the context of manufacturing – “Automation is using equipment to automate processes or systems. Manufacturing automation aims to improve production and reduce costs..”

How can manufacturing processes be automated? Artificial Intelligence and Robotic Arms among others help increase productivity and take the tedious work out of manufacturing. There are many automation opportunities in apparel manufacturing. It is as complex and complicated as any industry.

AI in Fabric Inspection: A new standard

Fabric inspection has been automated for years, but is seeing major changes. It is performed before production begins. Now special equipment can replace manual labour. They automatically inspect and classify the fabric and count the defects. Then, the detailing of the garment are stored for future reference. While fabric inspection technology or fabric defect identification has been around for many years, only few companies are now using AI-driven technology to inspect fabric.

Artificial intelligence aids the apparel sector in dealing with the high defect rate of textile manufacturers and clothing factories caused by fabric defects, high compensation rates and low manual recognition. The role of such AI-driven technology is even more important because manual identification information in fabric inspection process cannot be effectively transmitted and the industry cannot form realistic pain points such as unified standards, hence can’t reform it.

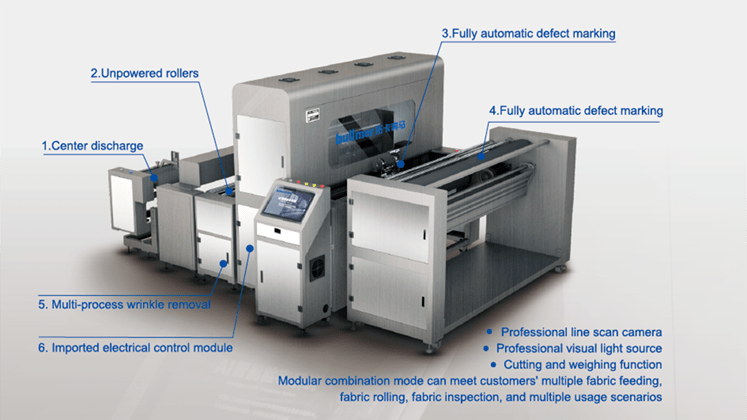

Bullmer – owned by China’s Jack Stock – marks its name as one of the first companies to launch a next-gen AI-driven intelligent technology – AI 01 – for the inspection of fabric. Bullmer’s AI-based Deep Model Self Learning technology and continuous self-evolution in fabric inspecting with Bullmer is a benefit to factories/mills in complex fabrics as it allows the machines to learn more intelligently, continuously. It integrates many image processing technologies. An industrial camera is used to perform advanced line scans. This ensures stability, detection and interference.

AI-driven fabric defect recognition technology offers significant benefits. Firstly, defect maps in fabrics can be directly formed using technology, and the data can be directly connected to factories’ management systems such as ERP, MES, etc., to facilitate judgment, management and problem handling. It is now easier to standardize fabric management. AI-driven machines can reduce high defect rates in companies that are usually due to fabric problems. This reduction rate is around 72% – 78 percent. The standardisation of defects identification parameters allows for this. The technology can be used for 24 hours uninterrupted and allows one fabric inspector to reduce the need for manual intervention. In 10 hours, the fabric inspector can inspect 20,000 metres of fabric in a single day using this technology.

Automation for cutting rooms

No longer are automatic cutters only used for cutting fabric layers in garment cutting areas. Cutting technology suppliers have today imbibed AI and ML in their machines to upgrade and advance pre-production process which is obviously a need in today’s time when machine downtime can hamper productivity and on-time delivery drastically.

These are the top-of-the-line cutters at the well-respected France-based tech group Lectra Many sensors are embedded in the machines, allowing them to detect when there is a problem. Lectra uses this data to determine if the customer is using the equipment to its best advantage. Lectra will use this data to find out if they’re not using the equipment in the best way possible and can ask the customers to modify certain parameters.

Similarly, Morgan Tecnica is based in Italy Machine to Machine (M2M), communication is its foundation. The automatic cutters of the company can accurately predict any potential breakdowns, including knife breaking or bearing failure, in advance. The new cutters have a variety of sensors that monitor the stress levels of the cutter’s most important areas. These sensors allow the company to inform its customers ahead of time that parts need changing or suggest that they adjust their settings so that there is no risk of premature breakdown.

The leading Eastman Machine Company is a US-based company that makes cutting technology. is also revolutionising the cutting technology as it’s embracing Industry 4.0 concepts – machine learning, M2M communication – in its auto-cutters. Eastman developed synchronised technology that digitalises motion control completely. When something malfunctions or becomes unusable, the machine sends a warning signal to the monitor and informs the user that it must be replaced. The company calls this ‘Robotic Indication System (ROI)’ that connects with the machine in such a way that it automatically tells which wiring is getting loose and it blinks on the monitor to inform about the defective part.

Automation on sewing floor – Automats, Pick and Place Systems

Sewbots – offered by the US company SoftWear Automation – made huge headlines a couple of years ago. The sewing machine was controlled remotely by robotics, and could sew T-shirts with no human assistance. Despite grabbing some attention from the apparel industry from around the world, the company couldn’t scale up the commercialisation. The main reason is that the company couldn’t deploy robots in other products than T-shirts!

Although it is impossible to fully automate sewing for many apparel products, there have been some innovations within the textile industry that could serve the same purpose. As factories have to be able to automate complex, labor-intensive tasks that were previously done by human workers, all these advances are being made with the goal of reducing human intervention.

Eine solche Innovation is Jack’s ‘Pick and Place’ system Through the robotic arm developed by Huawei and used in pattern sewer. In an exclusive demonstration, Team Apparel Resources, (AR) The pattern sewist is equipped with a robot arm that can control three different machines simultaneously. “This robotic arm equipped with Jack’s pattern sewer is our answer to the people who are looking for robotic sewing in the clothing industry,” shared Jack’s official with AR team.

It is possible to use two different patterns with the same automatic pattern-sewer. As a camera fits in the machine’s sewing head, the sewing machine is able to identify and stitch the templates visually. The robotic arm receives inputs from the sewing machine and automatically picks up the template and places it on the next station. This saves a lot of time, money, and increases productivity.

Germany’s recent advancement in automation must be credited for the breakthrough. Robotextile GmbH Four new gripper techniques have been developed by the company. They are capable of safe gripping most textiles, and then depositing them back very precisely. The single layers of fabric can be taken up the same as the entire stack. The Gripper A category is used for cotton, denim and suits. While Gripper B can be used for stiff materials, mixed fibrils and coated fabrics, Gripper Gripper Gripper Gripper Gripper Gripper Gripper Gripper Gripper Gripper Griper C for knitted and woven fabrics. Meanwhile, Gripper D can be used for underwear and statically charged fabrics.

Most of Robotextile’s grippers have built-in double-layer control and hold the textile in place by clamping as it moves. These grippers can be used for the following purposes: Coanda Venturi vacuum, glue dot rubber pinch roller silicone finger, glue dot and glue dot.

Italy-based Vibemac Since over forty years now, has been the leader in developing high-tech sewn automats for apparel industries. What Vibemac, as a company, is doing is that it’s developing sewing stations with Loaders and unloaders that automatically load or unload. The pocket hemming device V700/701 is an example of such a machine. This pocket hemmer machine has a modified version, V700LDR. It includes an automatic feeder station and 4 automatic loading docks. The special loading device transfers the pockets through a robot arm to the transport belt. After the pockets are closed, an unloader will automatically place the pockets in the correct order on the storage drive at the bottom of the transport belt. This is ‘intelligent automation’ – as termed by Vibemac.

AMP Pisani automatic bra moulding machine Another example of the ingenious way bra manufacturing has evolved is this: The AMP PISANI P88/4E Flexible Unit has 4 double molds. These pliers can make eight bra cups from one cycle. Laser-cut movable plates are used to eliminate creases for deep cups and low density laminated foam. “Not all molding machines in the market have movable plates and that’s an added advantage for us,” commented Foo Toon Paw, Managing Director of Focus Garment Tech – dealer of AMP Pisani in South Asia.

Focus Garment Tech offers another engineered product: Keki JD200; An automatic bra strap machine. Bra strap construction is easy. The strap passes through an 8-buckle mechanism, which increases the size and length of the adjuster parts from 40 to 120mm. One 400-mm size strap takes just 4 seconds, while an hour’s productivity yields 900 pieces.

Automated Measurement Inspection

The garment measurement process is one such process which takes hundreds of man-hours to measure a huge number of garments in a factory on a daily basis, yet there is no certainty if the measurement is accurate and the passed garment won’t fail at the receiver’s end!

Quality inspectors often find themselves in a difficult situation because of the high likelihood that human error is involved with traditional measuring. Traditional apparel factories face many challenges in garment measurement, which can negatively affect their profitability. One of these challenges is high time consumption in the manual measurement system. It takes around five minutes to measure a garment and record it. The time required to enter data into a computer program is about 5 minutes. If the product is difficult to measure, it takes even longer.

Suppose a factory requires to measure 10,000 pieces, then around 50,000 minutes of the total garment inspectors are dedicatedly required which leads to only two solutions – 1) either increase the number of workers involved in the measuring process or 2) increase the number of days to conduct the process before it goes to the subsequent process. Both cases require that the factory consider indirect costs when planning for projects. The average garment QC worker spends between one-and-a-half and four hours a working day entering data into Excel, PDF, or other formats.

Another issue is the high chances of human errors throughout the measurement process, as the traditional method of size measurement and data entry is prone to all kinds of human errors. The deviation from the spec size is often calculated by quality inspectors before they write down the difference. It adds mental strain and exposes inspectors for uninvited errors.

Access to data is the third major issue as the current method of size measurement and results in analogue data hinder the factory’s business from making correct, real-time decisions across various operations and this adds woes to the already flawed process. These problems can all be overcome by digitalizing the entire garment measurement process. There are also intelligent technologies on the market to solve them.

A South Korean company – Bagel Labs – introduced Bagel Size Measuring Solution (ALT Smart Tape) sometime ago, and the same is offered by Sakho, a sister concern of the H&H group. The measuring solution utilises Bagel Labs’ proprietary smart tape measure technology to measure size digitally and send data directly to the computer via Bluetooth. The ‘smart’ tape can measure up to 160 cm (63 inches) and has an error range of just ±0.5 mm which makes it the world’s most accurate digital measuring tape, according to the company. It is also compatible with Microsoft Excel as well as most ERPs and PLMs.

Innovations have been made in the measurement process. Dongguan Yunji Zhihui Technology Co., Ltd.Company based at Dongguan High-tech Development Zone (China) is a developer of high-tech industrial intelligence equipment and provider of technical services. It recently introduced its highly-tech garment vision inspection and measurement machine, equipped with the vision technology. The system has filled the gap in the apparel manufacturing sector’s visual inspection system.

Garment visual inspection machines use computer-vision inspection systems as their core technology. They also incorporate artificial intelligence (AI) and automated hardware mechanism integrations. This machine is based on an existing assembly line design. Tested T-shirts are placed on the belt/bed of the machine. Any parts not covered by the cloth can be identified.

Once the garment product enters the machine, the screen, after 6 seconds, automatically shows the message – Pass/Fail, with all measurements. The machine can identify errors and automatically calculate them. It is able to quickly and accurately determine the garment’s size, especially T-shirts. It can automatically detect product information, and produce various quality reports that are required by apparel factories.

For example, if a T-shirt passes through the machine, it automatically measures the 15 dimensions of the T-shirts in maximum six seconds which are – collar width, collar depth, left shoulder width, right shoulder width, left sleeve length, right sleeve length, left sleeve width, right sleeve width, chest width, waist width, T-shirt length, T-shirt width, sleeve length symmetry, shoulder width symmetry and cuff width symmetry.

Automating the Garment Folding process

Conventionally, hundreds of workers used to spend hundreds of hours to manually fold the garments of different types on a daily basis in a typical export-oriented factory and the situation is no better even today despite the fact that automation has paved way for the betterment of a factory’s shopfloor processes.

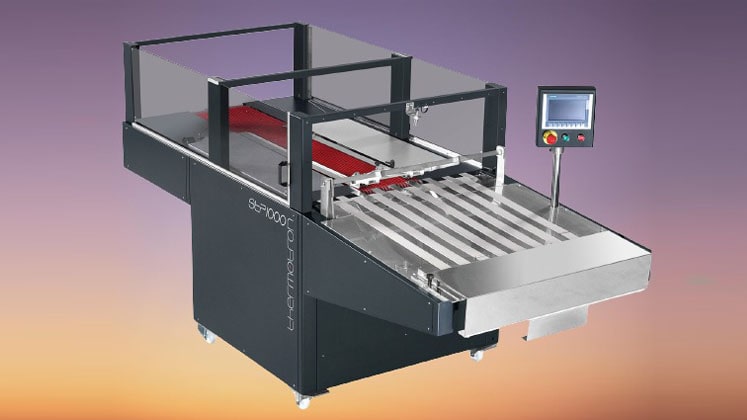

Thermotron’s Automatic Folding Machine Line STP 1000 comes either as an autonomous unit or as part of a folding and bagging machines set and the machines are – STP 1000 (automatic folding machine), PV40 (automatic bagging machine) and KL60 (automatic sealing machine). Fully automatic machines can bag, fold and seal 5,500 garments with one operator in just eight hours.

“The variety of garments is huge, and, for each garment, we have different reaction from the machine but our engineers have been able to make a line of machines that can be used to fold all type of casual garments like T-shirts, Polo Shirts, Sweaters, Jeans Bottoms,” commented George Paschalidis, Sales Manager, Thermotron. Thermotron has an automated stacking machine called NT50 that is capable of folding garments already folded.

Shenzhen Lingchuang Automated Technology Co. Ltd. Since more than 10 years, the company has focused on automated garment folding and packaging technology. The company, with over 40 patents and a production capacity of more than 400 machines annually, is equipped with a state-of-the-art R&D centre where it invests in cutting-edge innovation and customization.

A series of packaging machines requires only one person to hand feed the garments (knits, trousers) while the folding, sealing and packing are automated. The result is a more efficient and productive packing process. It packs between 500 and 700 pieces an hour, which is approximately 5000 per day. This increases packing efficiency while reducing manpower for manual folding and packing garments. The leading Chinese machines are approved by world-renowned brands such as Nike, Uniqlo, Adidas, Anta, H&M, Gap, Super Dry etc., as claimed by the company.

It is impossible to complete the list without including Portugal-based ROQ that offers the ROQfold automatic folding machine that’s said to fold any kind and shape of clothing such as T-shirts, sweatshirts, polos – short or long sleeves – trousers, skirts, dresses, etc. The secret to this flexibility of folding different products is its three folding stations – sleeves, body and final fold. ROQfold offers two options: (1) with three folding stations and (2) without sleeves folding station. This allows the machine to take up less room in the factory. This second configuration is recommended by the company to only fold T-shirts.

One operator is required to load each piece, and the machine handles the rest. For smooth operation, the only requirements are the initial configurations of the lengths and types of folds. This depends on the size and type of your pieces. Then the automatic process begins.

The processing speed of ROQfold is 700 pieces/hour which can vary depending on the size and type of the garment that’s loaded in the machine. To ensure that all work is done correctly, the loader defines the speed of the machine.

Automating 25,000+ hours of Manual Work – Levi Strauss’s Way

Popular denim brand Levi’s has scaled up its automation programme drastically. The Levi Strauss & Co. Robotic Process Automation (RPA) Center of Excellence (COE) team set out to automate nearly 25,000 hours of tedious work by the end of 2022 with 45 in-house bots.

The bots take away the monotonous task of data entry and validation and allow workers to focus on analysis. RPA COE has collaborated with many functions in the organization and across the globe, including IT and merchandising. This team helped to manage workloads and enhance efficiency.

“In late 2021 and early 2022, I embarked on a mission to educate LS&Co., about the power of automation, and I think with the results of 2022, we have proven the benefit. Now it is a question of how far we can go,” said Stacie C. Clarkson, Senior Director for Process Transformation and Global Business Services Governance. Lead of the RPA COE.

Stacie also commented on the fact that automation ambassadors have been created across the business. The company beat its goal of 5,000 hours, which is proof of the benefits that employees can reap. Levi’s has even more work underway and plans to automate at least 45,000 hours of work by the end of 2023.

Global product development was one of the functions that used the RPA COE in 2022. The Levi’s® brand is a full head-to-toe lifestyle brand that offers staples like fresh graphic tees each season. Normally, the product development team would be responsible for combing through thousands of graphic tee product codes and cross-referencing them in its digital asset management tool, ensuring all the information and visuals are accurate and included in the briefs before sending to its manufacturing partners — a task that would take hours.

Together with the product team, RPA COE developed a bot which would validate and verify thousands of product briefs. It also flagged those files that required reconciliation such as incorrect file types and missing visual links. Now the team can focus more on solving the problem than looking for it.

“With the bot developed by our RPA team, our team is saving nearly 450 hours a year, and we’re able to be much more efficient and effective in our validation process,” said Jonathan Hsieh, Levi Strauss Product Development Manager.