In a significant breakthrough earlier this month, Avay Biosciences, a Chennai-based deep tech startup, launched their indigenous ‘state-of-the-art’ bio 3D printer that can print human tissues.

Called ‘Mito Plus’, the printer was launched during the Bengaluru Tech Summit held between 16 and 18 November 2022. This milestone is important, but why?

Before answering this question, it’s imperative to understand what bioprinting is. It’s a method of tissue replication that uses ‘bioinks’, which are engineered to print artificial living tissues like skin.

What exactly are bioinks?

Speak to Better India, Manish Amin, CEO of Avay Biosciences, says, “Bioinks are gels or pastes which contain two key components — the cells for the type of tissue we are targeting, and biomaterial that can support the cells and aid their growth. The chemical processing of natural resources like cartilage, bone and meat allows for the creation biomaterials such as collagen and gelatin. They imitate the cell’s environment as it would have been within the body, and so are used as support structures (scaffolds) upon which cells grow and connect.”

In a recent release issued by Avay Biosciences, they note, “Bioinks are materials engineered to allow the specific type of cells to grow and multiply while supporting the tissue’s structure.”

These can be divided into one of the following:

- Structural – These inks are used to create frameworks or supports for the structure.

- Sacrificial – These inks are aimed at supporting structures during the printing process but are later removed or consumed by the cells to be replaced by their own materials.

- Functional – These inks are used to guide a specific function like cellular growth, development and differentiation.

Is Mito Plus essentially creating new tissue from human tissue when it prints tissue human? These bioprinted tissues are very similar to human tissue in the body.

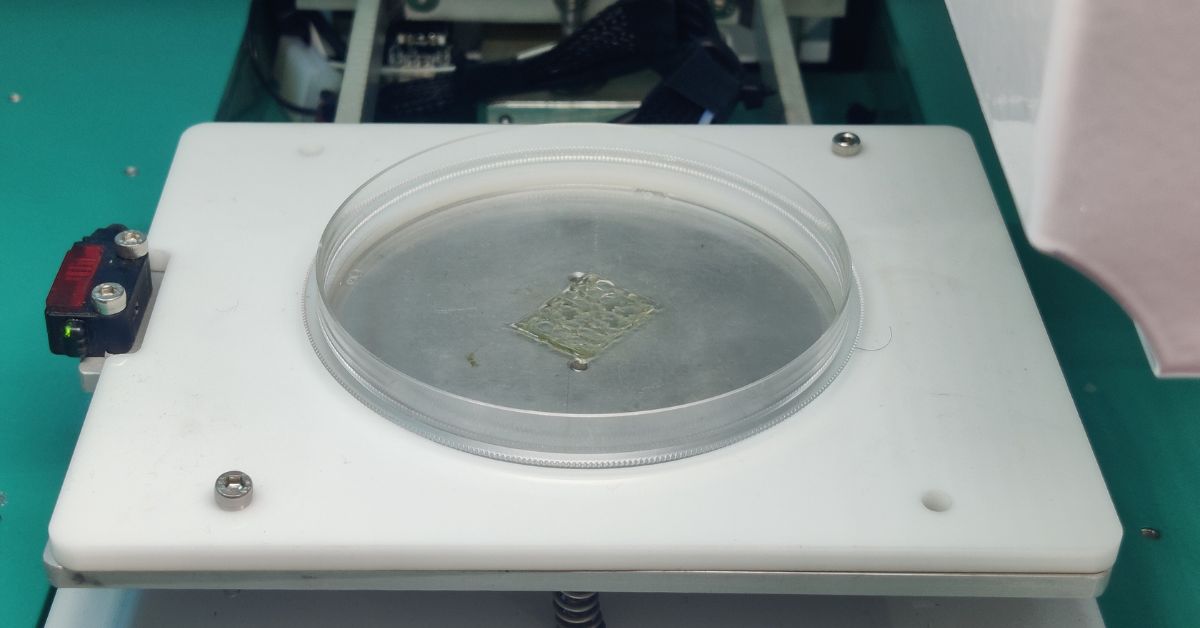

Manish notes, “Printing tissue currently means using bioinks — cells mixed in biomaterial — to create scaffolds. Incubation is necessary to allow the scaffolds to develop and grow in the correct environment. Scientists are currently trying to verify that the complex scaffolds behave exactly like real tissue. Identifying these differences would lead to huge steps forward in understanding and artificially growing entire organs — something that globally we are still aspiring to achieve.”

The evolution of the bio-3D printer

IISc, Bangalore was the place where Mito Plus’s prototype was first installed. The advanced version of the bio 3-D printer we can see today was created with inputs from the prototype developed by Dr Bikramjit Baseu’s research laboratory.

Avay Biosciences offers completely in-house development of software and hardware to create end-to-end 3D printer solutions for India.

“We originally built the Mito Basic prototype. This was easy to do and took only four months. Many college students are now trying to make their own bioprinters at home. It was difficult to move from prototypes to products. Are all software issues fixed? Is it possible to print multiple times? Can we provide better quality parts and features?” asks Manish.

All this led to them expanding their design, manufacturing, electrical and software teams to build something that soon was far removed from the original version — a true bioprinter.

“There were many small improvements along the way — adding systems for temperature control, many trials of different UV bulbs and LEDs, and after many mistakes, we now have a system that is ready to launch in the market. However, there are always imperfections. We will continue to resolve existing issues and develop new and innovative features that our customers keep asking for until our printer is the default for all tissue engineering research,” he adds.

Avay Biosciences is the first company to develop 3D printers. Around 70% of production takes place in Chennai or Bengaluru. Their software development team is dedicated to continually adding features and improving the software.

‘State of the art’

“MITO plus is one of the most advanced bioprinters in its price range. You can print many biomaterials with this printer. It also includes UV curing. HEPA filters are included in the printer. The temperature control is the most important feature. Both the printhead as well as the bed of the printer can be heated or cooled to temperatures up to 80° Celsius. It can also be used to test and discover pharmaceutical drugs. It can also be used in cancer biology and cosmetology applications,” says Manish.

What are these characteristics that facilitate bioprinting? Many biomaterials are quite temperature-sensitive and require precise environmental conditions.

“By controlling the extrusion temperature, the viscosity of the material can be controlled to an extent. These feedback were provided by our two key collaborators, Dr Bikramjit Bazu on bone tissue creation and Dr Prajakata Jain from the Institute of Chemical Technology (ICT), Mumbai in skin tissue engineering. Hence, this is an important feature we wanted to develop,” explains Suhridh Sundaram, chief operating officer, Avay Biosciences.

“This allows the researchers to be able to adjust the printing parameters and fine-tune it for precise scaffolds. UV light can also cause some materials to harden or cure. Since these materials are gels, to achieve more layers we need such curing or else the bottom layers get compressed and do not maintain structural integrity,” he adds.

Future applications

A subset within the wider 3D printing market, bioprinting. Most 3D printing is done with plastics, but bioprinting can be achieved using live cells or gel-like polymer material.

The principle of bioprinters is the same as those used in 3D printing, but there’s one important difference. Bioprinters don’t deliver metal, plastic or powders. Instead, they deposit layers of biomaterials. These biomaterials may contain living cells that can be used to create complex structures such as skin and liver tissue.

“3D bioprinting is a unique gift to humanity by science and technology. There are still many problems to solve. There is still a long way to go before we can create fully functioning and viable organs for human transplant,” says Manish.

The availability of affordable bioprinters is essential for developing artificial organs. Future research relies on it. In India alone, many people die each year due to the shortage of donors for organs. Transplants, even when a donor is found, can be more expensive than Rs 10 Lakh, and that does not include anti-rejection medication.

Suhridh explains “Our approach to the creation of entirely new organs begins with the journey of creating new tissue samples — a critical stepping stone for a very long-term and difficult journey. In collaboration with ICT Mumbai, we are working on having our printers develop skin — the most common type of layered tissue that could help victims of severe burns. This tissue can also be used in toxicology screenings and other testing. People can contact us for more details on the research being conducted, and how we can help your mission.”

Meanwhile, Manis adds, “There are other applications. For pharmaceutical companies, to be able to test drugs on lab-grown tissue instead of facing regulatory hurdles of animal trials and human clinical trials would greatly accelerate our capability for research into new molecules, and identify risks much earlier on, thereby saving research costs that do not bear fruition.”

Avay is a long way from creating a bio-3D printer to create artificial organs.

“Avay is very far indeed from artificial organs. The research is ongoing. This multidisciplinary research project requires the assistance of tissue engineers and material scientists. They will need to help develop biomaterial scaffolds and stem cell/regenerative medicine practitioners. Surgeons and surgeons are needed for the most effective way to implant these organs. We continuously take feedback from all these relevant parties and are working on the engineering as well as biomaterial side for now to give researchers the best solutions that can be imagined,” notes Manish.

The startup has already partnered with top research and development institutions across India, including IIT Madras and ICT-Mumbai. Avay Biosciences is a startup that leads the charge in India’s private sector.

As per several reports, there is a global 3D printing market that is worth USD 1.3 billion at the end of 2022. It is expected to rise to USD 3.3 billion in 2027, according to projections. It is in high demand both within the cosmetology and pharmaceutical industries.

You can find out more information about Avay Biosciences at their website. All images by Avay Biosciences.

(Edited By Divya Sathu