A go to to Mimaki has rekindled Stephen Holmes’ appreciation of color in 3D-printed prototypes. However, as he studies, current developments make color price contemplating for engineering fashions in addition to for CMF workflows

Few areas showcase an abundance of color like the town of Amsterdam throughout its annual Satisfaction Weekend.

As soon as by means of Schiphol airport, full of Dutch orange soccer shirts heading off on trip, and a riot of rainbow flags arriving in time for the occasion, we headed to printer producer Mimaki’s European headquarters, the place we discovered the Japanese firm placing on an equally vibrant show.

Mimaki-s UV-cured inkjet printing is an evolution of the model’s 2D giant format printers, which fill many of the demo house at its European base. On present are the corporate’s most artistic improvements for printing designs immediately onto supplies such cotton materials, clear polymers for window shows, and even 3D objects reminiscent of pens and water bottles. Mimaki’s 2.5D know-how is constructed to function in excessive turnover manufacturing environments and shares a lot of the identical mechanical design DNA as its 3D printing brethren.

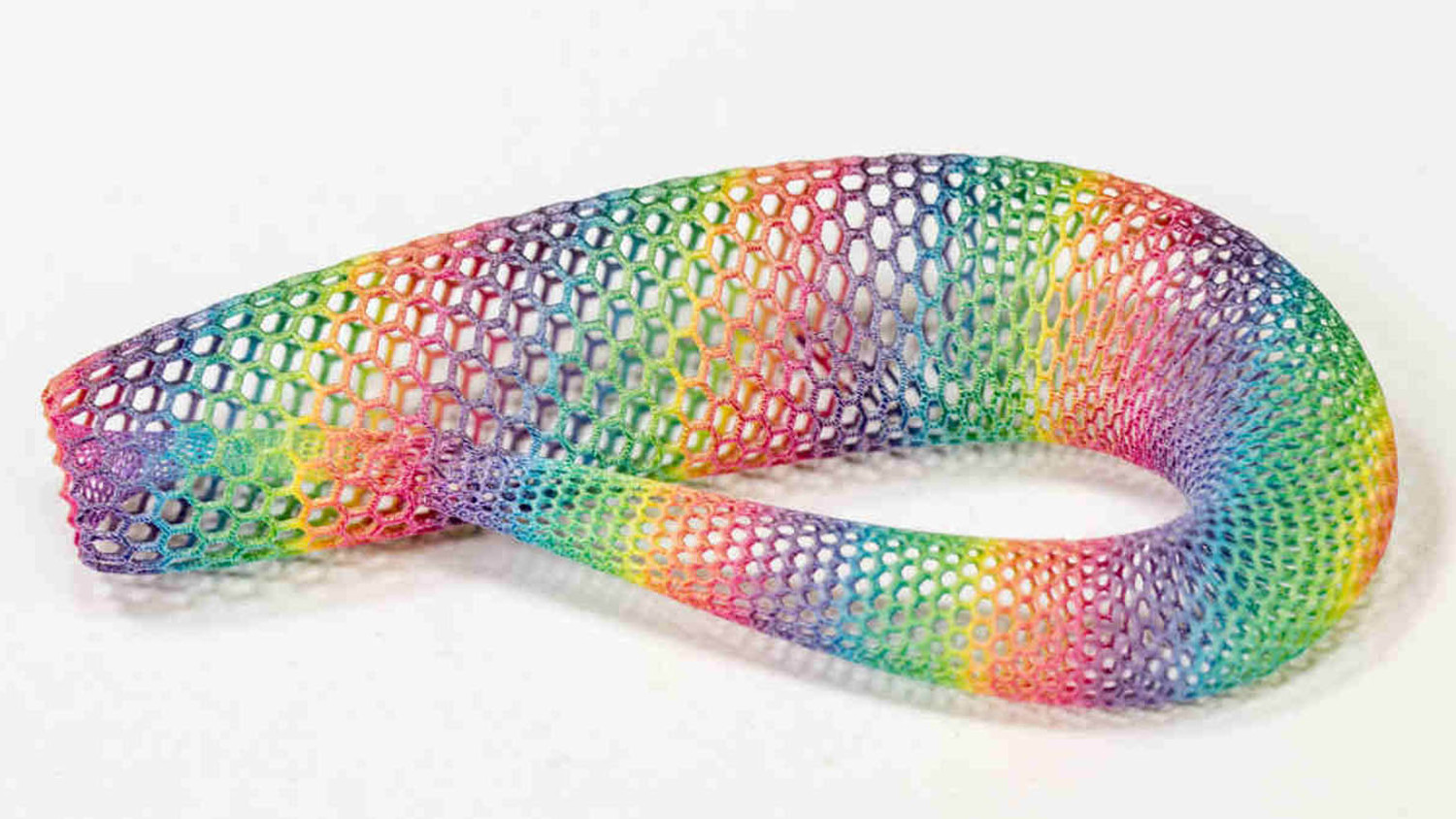

Mimaki’s two 3D printers, the 3DUJ-553 and smaller 3DUJ-2207, occupy their very own section of the constructing, surrounded by an array of fantastical 3D fashions, from medical guides to magical statues, and from pairs of sneakers to architectural fashions. The corporate gives no ‘purposeful’ supplies for stronger or elasticated elements. As a substitute, the main focus is on reproducing over 10 million colors in excessive element.

What you are able to do with these colors is spectacular however comes with some limitations. Whereas quick post-processing of Mimaki elements makes them extra sturdy than you may anticipate, they’re not designed to face as much as excessive temperatures, for instance, and components reminiscent of hinges will present indicators of damage after time. Nevertheless, the place this know-how excels is in placing throughout an concept, promoting an idea or explaining a course of as a tangible half.

Overcoming obstacles

Color 3D printing has been round for over a decade, but uptake has been restricted by two elements. First, there’s the faff concerned in digitally colouring a CAD mannequin and getting that to work. Second, there’s the standard of what comes off the printer.

There have been important enhancements in each respects. Output from immediately’s machines is way extra reasonable. The provision of colors, the power to create pure hues and the introduction of clear supplies all characterize important steps ahead from the washed-out, powdery finishes of older technology Z-Corp machines. Software program workflows have improved, too. Early efforts sometimes concerned huge file sizes and a variety of handbook involvement.

In pursuit of a extra seamless Color Materials End (CMF) prototyping workflow, for instance, Stratasys has labored alongside visualisation professional Luxion to develop a easy, full-colour export from Keyshot renders for its J-Sequence 3D printers. This print information comes packaged in a 3MF file format, superior to STL recordsdata and able to containing the color and texture information for reasonable prints. For the reason that Stratasys-Keyshot launch, extra workflow choices making use of the 3MF file format have grow to be obtainable, reminiscent of by way of Autodesk’s Netfabb.

Utilizing this course of, Autodesk’s Boston know-how centre has been experimenting with color prototypes, utilizing fashions designed in Fusion 360 and utilizing Netfabb to use and export color information to its in-house Mimaki 3D printer to provide the ultimate fashions.

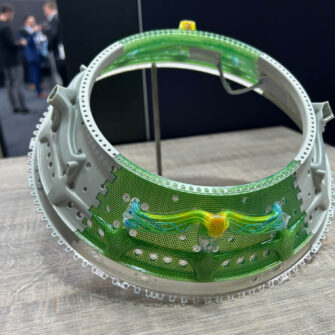

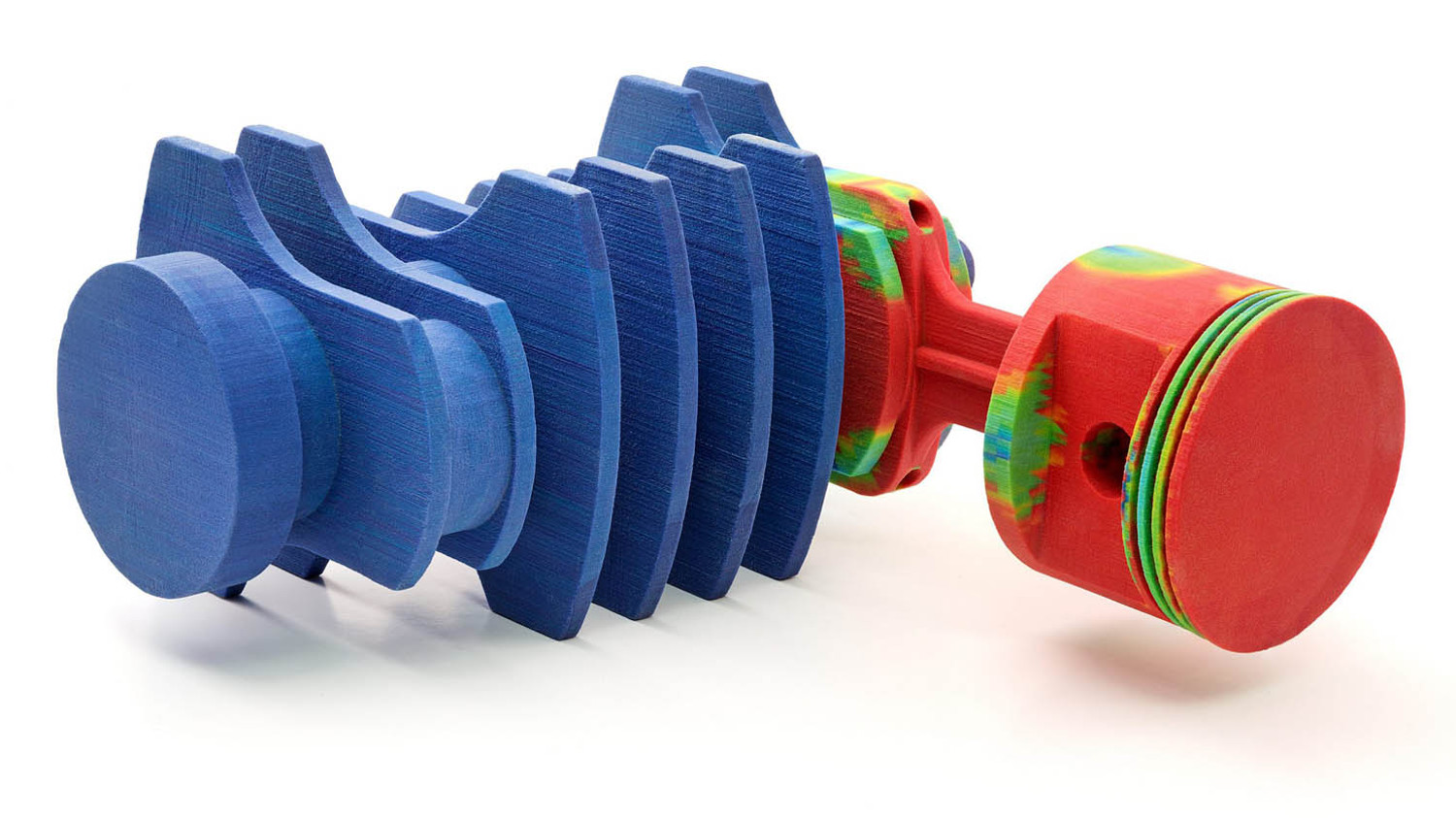

Scale fashions are nonetheless precious instruments for explaining designs and getting buy-in from stakeholders, and for elements with advanced lattice infills or digital layouts, or for displaying the outcomes of stream simulations, a color 3D printer actually brings a proposal to life.

In spite of everything, duties reminiscent of explaining the results of a mould stream simulation or the efficiencies of an inner lattice cooling construction are loads simpler when a mannequin that illustrates the benefits in full color may be laid on a desk, handed round and inspected. On a much less advanced degree, color may be actually helpful for labelling a mannequin or distinguishing totally different components in a prototype.

On this manner, a journey into color can be a greater option to lay out the details in black and white, so that everybody can see and perceive what’s occurring. Simple on the attention and simple on the mind.

Stratasys J850 Prime

The flagship of Stratasys’ Polyjet UV-cured resin 3D printers, the J850 Prime comes with Pantonevalidated colors and multi-material skills that give flexibility for prototyping a variety of merchandise.

With excessive accuracy, textures may be added to elements to boost the realism, or just add effective textual content or element to a print – like digital shows, woodgrain or stitching – bringing much more choices, along with the halfmillion colors it may possibly output.

A large materials choice gives impressively translucent and rubber-like choices, whereas a spread of biocompatible supplies and digital ABS for highimpact energy and warmth resistance provide purposeful prototyping skill.

If it’s color that you simply’re trying to deliver in-house, Stratasys says it may possibly produce full-colour fashions straight out of your Keyshot render in 20% of the time it takes to provide a standard painted mannequin. When you refill the 490 x 390 x 200 mm construct platform with choices, then this new skill for design assessment solely takes on extra promise.

www.stratasys.com

HP MJF 580

Killed off after solely 4 years in manufacturing, HP’s color 3D printer can nonetheless be discovered arduous at work in some service bureaux, and with good cause. The elements it produces, when post-processed, are harder than the competitors and the method is comparatively quick. This enables for customised, purposeful end-use elements (reminiscent of prosthetics) to be constructed and to enhance or stylise a product to the person person’s tastes.

Elements are excessive density and low porosity PA 12 Nylon, which itself is fairly sturdy, however is additional enhanced by post-processing. The flexibility to work with color on the voxel degree means easy gradients and 1,200 dpi crisp particulars proper throughout the 332 x 190 x 248 mm construct space.

A variety of post-processing methods may be utilized to get probably the most from the elements, most of which may be automated, from major blast cleansing by means of to vapour smoothing that enhances colors and will increase mechanical properties.

www.hp.com

Stratasys J55 Prime

On the different finish of Stratasys’ J-Sequence product line is the J55, a scaled-down, design studio-friendly model of the J850, designed to pop off color fashions at will.

Its rotating, round construct platform manages to squeeze in additional than anticipated for a printer of this footprint, whereas the J55 has been developed to sit down alongside designers with minimal noise and odour, and gives easy water-soluble helps.

The extensive color vary continues to be right here, as are digital supplies reminiscent of VeroUltraClearS, which may simulate glass and plastic in a spread of color tints, and Stratasys’ Elastico versatile photopolymer, which in clear or black variations has excessive elongation to offer it breakand tear-resistance.

The one factor which may sluggish you down if utilizing this machine at full capability is usually altering the only litre materials cartridges, in comparison with the 16-litre models discovered on the J850.

www.stratasys.com

MimakiI 3DUJ-553

The title and look of the 3D printer may appear industrial, however that’s squarely the purpose while you see the 3DUJ function alongside different merchandise from the Japanese model.

What the unit forgoes in memorable titles and comfortable angles, it makes up for in eye-popping 10 million color output, which because of Mimaki’s industrial printing heritage, makes use of ICC color profiling for constant and repeatable outcomes.

The 2D printing heritage reveals in easy color gradations, because the printer appears to be like to minimise granularity throughout its 508 x 508 x 305 mm construct quantity, whereas Mimaki has additionally developed a transparent resin, permitting full transparency and semi-transparent color to be realised.

In a position to print in 19, 32 or 42μm layers, super-fine textual content element and easy surfaces may be achieved, whereas water-soluble helps protect edges and delicate components.

www.mimaki.com

3D Programs ProJet CJP 660Pro

The grand previous dame of color 3D printing, the ProJet CJP is displaying its age. It’s a ZCorp 3D printer with a facelift and a few gentle upgrades alongside the way in which for the reason that firm was acquired by 3D Programs over a decade in the past.

However as ever, age is simply one other manner of measuring expertise, and whereas no person will probably be fooled into pondering elements produced by way of 4-channel CMYK output that maxes out at 100μm layers is the actual factor, it may possibly print full-colour fashions at a velocity of an inch an hour, making it each the quickest and least expensive 3D printer on this listing. This frugality additionally applies to supplies, with the bottom powder comparatively low-cost in comparison with resin. What’s extra, unused powder may be reused.

With a construct space of 254 x 381 x 203mm and no helps needed, you possibly can see why these machines proceed to run in workshops the place ‘fast and soiled’ prototypes from easy OBJ recordsdata are wanted.

www.3dsystems.com

Dyemansion Dyed SLS, SAF and MJF elements

White Nylon elements, constructed by way of SLS or HP’s MJF course of, may be post-processed to tackle block colors.

A rudimentary color bathtub can do the job, however for scale and color accuracy, you’re finest an automatic resolution like Dyemansion’s DM60 collection, which additionally suits as a part of a full post-processing cleanup and ending set-up with cloud monitoring.

Clear elements go in, and 150 minutes later, color elements come out. Easy.

www.dyemansion.com

Carbon all M- and L-series

If single-colour, end-use elastomer elements are what you’re about, then Carbon’s lately introduced EPU 46 materials, which helps direct resin colourisation, ought to definitely be in your radar.

Customers can combine their colors with opaque and clear variants, creating daring colors in a rainbow of various shades.

With a shore-hardness between 55 and 78, customers also can finetune the fabric stiffness of the elastomer.

www.carbon3d.com